Supplemental Materials

Optical

fiber light source directs neurite growth

Forrest Jesse1*,

Zhenjiang Miao1, Li Zhao2, Yao Chen2, Yuan

Yuan Lv2

1Human Computer Interface Lab,

Beijing Jiaotong University, Beijing, 100044, China

2Department of Physiology, Beijing

Sports University, Beijing, 100084, China

*jesse@jesse.org

1. Fiber Tapers

The simplest implementation of the

fiber taper is a relatively wide taper that is stiff enough to not bend under

its own weight or be pushed by the liquid it is immersed in. The tapers we found most easy to work with were similar in width to a

neurite. Without adding lenses or shaping

the end of the taper, our wide

(micrometer) taper will cause a wide beam, which in our experiments

often encompassing the entire growth area of the neurite. Unless energy is

closely regulated according to the emission tip’s distance

from target, a wide beam can cause neurites to quickly (within 5 minutes) be thickened by too much

radiation, causing growth to stop, perhaps permanently. Narrow beams can be

accomplished by creating a narrow taper

(which we created and used but found difficult to move),

or by possibly

shaping the end surface of the

taper into a lens or adding other optics. Our experiment dealt with a simple fiber taper only and did not add

optics to its end or shape the end other than as flat and as half-sphere.

A variety of fiber tapers with

similar but varying optical characteristics were created. Best results were

achieved with a fiber which tapered to 1 micrometer through a length of 1 cm,

ending in a smooth, regular and un-chipped tip. 1 cm long

uncurved tapers were found to be

the best compromise between optical precision and fiber manipulability as light

loss is minimized and short tapers bend less at the air-liquid interface when

being partially immersed in the cell culture solution.

1.1 Taper Characteristics in Detail

Fiber tapers were analyzed under a

microscope[j]. Tapers of two shapes were

selected: a “narrow”class

of tapers with a tip width of 0.1μm (as narrow as the cell neurites) and a “micrometer”class of tapers, with a tip width of 1μm (1x to 4x the width of the neurites). Viewing through a video microscope[k] allowed eye safe visual

characterization of the emitted beam by projecting it through a cloudy

solution. Narrow

tapers were found to have lower divergence of 15 to 30 degrees because the

emitting end was flatter. The

narrow type also had higher light loss

which could be linked to bending (up to 45 degrees) of the fiber at the air -

liquid interface where the fiber entered the liquid in the sample dish. Micrometer tapers had a projected beam with

a 45 to 120 degree divergence and less light loss, the fiber was unaffected by

bending at the air-liquid interface. Beam divergence in

culture liquid was low (less than 5 degrees) for

fiber tips that were flat, and high (15 to 120 degrees) for rounded fiber tips.

Micrometer

tapers were then created with

a divergence near 90 degrees.

We did not

re-coat the exposed fiber taper area with a new reflection layer, which,

considering that the refractive index of water10 (about 1.3) and that of fused silica11 (about

1.5) are so close, care must be taken to keep the fiber straight as small bends

will leak light. For this reason we chose to use thicker fiber tapers which

were less prone to bending when unsupported.

We tried fiber tapers with many diversion angles between 90o and 10o, but the fiber tapers we used in this experiment had a diversion measured to be 90o or

1/4th of a sphere.

1.2 Measuring beam characteristics under the microscope

The refractive index of air9 is about 1

and the index of water10 is about 1.3, so beam divergence from

the fiber tip measured in air is higher than in the culture liquid (which is

mostly water) The refractive index of the silica fiber11 is about

1.5. We measured beam divergence in culture solution by directing an LED laser emitting

808nm light into the fiber. The fiber was immersed in a cloudy culture solution. In a light-sealed

laboratory operators wearing laser safety glasses powered on the laser and set

an emitted power of 500mW. The beam from the fiber taper was projected in the

cloudy solution and imaged by the video microscope which is sensitive to

infrared light. The beam profile was measured from the microscope image to determine

divergence (figure 5).

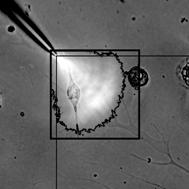

figure 1

The

dark black line surrounding the white area represents edge detection of the

beam, which can be compared to a 90o angle line superimposed on the image, showing near

90o divergence. Image contrast

increased, cropped.

Fiber

characteristics such as bends and imperfections in the fiber taper influence

light loss through the fiber. We primarily used the wider and higher divergence

micrometer class of tapers as this type had the least light loss as measured

through the microscope. The

rapid drop-off of energy with distance makes the ideal region of influence a

narrow band between 1 and 5μm from the end of a taper with 90

degree divergence.

There

is a change in the direction of extension of the growth edge toward the taper

tip within 2 or 3 minutes when the taper is emitting about 135mW with a

distance of between 1 and 5μm from the neurite

growth edge.

The energy of the beam can be approximately modeled as the following

relationship:

![]()

where

divergence div is 360o/90o = 4/1 = 4; r is

distance to a 1 μm2 section of the target neurite. The model is diagramed in figure 4, showing v1,v3,v5,

as

increments of distance from the source of radiation at origin o0. Radiation

is about 161mW into

the fiber and light loss is about 16%, so the imaginary sphere surface at v1

has 135mW over a section with an area of about 3μm2.

1.3 Beam directability and usability.

The narrow fiber tapers produced

the least directable beam as a great percentage of light was lost before

emitting through the taper, the fiber was narrow enough to be highly influenced

by the air - liquid interface at the top of the sample dish, and was influenced

by fluid currents in the dish and was subject to drag induced bending when

moved unless supported externally. The large taper produced a well defined beam

with higher divergence, and was easy to precisely position.

1.4 Fiber Taper Construction

A 2m multimode optical fiber[i] was cut in half, and the

outside cover layers were stripped away with scissors. A 10cm section of the

interior fiber with the inner glass, reflection layer, and two outer polymer protective layers

was trimmed bare. The two outer protective layers were cut

through with scissors to the reflection layer. The protective layer was

carefully pulled to leave a gap of bare glass fiber between two protected

sections. The fiber's two protected sections were gripped with two hemostat

clamps and the bare section was heated over an alcohol flame while pulling the

fiber firmly to stretch and taper the fiber, and finally sever the two

protected sections. Varying heat, stretching speed, and tension allowed the production

of tapers down to 0.1μm (and less) wide and with tips varying from flat (when the

fiber cools more quickly) to semi-spherical (when the

fiber cools more slowly).

2. Light

power

The laser used in this expirament[l] is a 500mW 808nm

diode laser, calibrated in 2011-5 and 2012-7, the laser diode is directed into

the fiber through a two element lens. The fiber coupling is a FC connector for 150μm core (multimode) fiber.

We calibrated the light output from the end of the

fiber taper using a 1 cm2 silicon photodiode with a plastic

attenuation filter covering the diode so that the diode has a linear[16] light-to-current

response from 3mW to 150mW. The current generated from the photodiode receiving

light from another new, recently power-calibrated known-power laser source (measured

after the fiber) at 135mW was measured and then adjusted our expirament laser

to reach 135mW after the fiber tip.

We built a calibration curve linking the control

values for the laser power to fiber tip output power values. We then chose 135

mW as a permanent output value. All power variation was then managed as a

distance value of fiber tip to neurite surface and laser output power was held

constant. The laser was given a 20 minute warm up period.

Light

loss at entry into the fiber and attenuation8 in the

fiber is about 16%, 161mW output from the laser is about 135mW exiting from the

fiber taper.

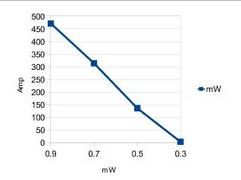

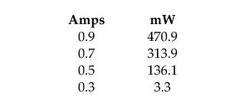

figure 3

Calibration

profile (2011-5) for the laser used in the expirament[l], We calibrated an after-the

fiber power for 135mW using the current from a photodiode and cross comparing

with another known-power laser (again after the fiber).

This is a simple laser power meter. The particle

content of the emitted light can be measured with a photocell, where each

photon interacting with the cell will release a photoelectron. Minus losses of

photons due to their not reaching or not interacting with the photodiode, we

have electrons that are measured as a current from the cell.

Photon flux can be measured with a photodiode if

adjustments are made for the particularities of the diode and its environment. 1mW

= about 3.9 x 1015 photons/second (and photelectrons/second from the

photodiode).

The photdiode will have a current response to

light, which is linear in a range that varies with each diode[16]. Our diode’s

linear response band is from 3 mW to 150mW after adding an attenuation filter.

The response plateaued after about 170mW. Response varies with temperature, but

this effect is far less than 1mW error per minute, our measurement was averaged

over 1 minute.

The light output drops off quickly with the

distance between the detector and the fiber tip, because the divergence of the

light emitted from the fiber tip is about 90 degrees, so we used a large photodiode

and placed the fiber tip close to it.

2. Cell Cultures

Two types of cells were used. Rat

cortex neurons[a] were extracted from rat pups

within 24 hours of birth, and PC12 cells[b] were cultured from frozen stored cells.

2.1 Rat cortex neurons:

2.1.1

Culture liquids:

Hepes buffered saline (“HBS”)

containing 10 mM HEPES[c], 140 mM NaCl, 5 mM KCl, 2mM CaCl,1mM MgCl, 10 mM glucose[d], pH 7.3, was always

filter-sterilized before use. Trypsin solution (bovine pancreas) [c] was dissolved in HBS to

1.25mg/ml plating and feeding media comprised of DMEM supplemented with high

glucose[e], 10% fetal bovine serum (“FBS”)[f], penicillin (100 U/mL) and

streptomycin (100 μg/mL)[e]. Glutamine[g] was added to the media on the

day of use by diluting frozen stocks to a final concentration of 2 mM.

2.1.2

Culture dishes:

Plastic culture dishes[h] were coated with

L-polyornithine[c] prior before use. After 2 hours

of incubation, dishes were washed twice with DMEM before use.

2.1.3

Process:

Cortical tissue was isolated under

sterile conditions, rinsed in HBS, the meninges were removed and cut into 0.5mm

pieces. Tissues were placed over ice while being operated on.

The minced tissue (approximately

0.2 mL) was then treated with 4ml 0.125% pancreas solution for 15 min at 37°C

with gentle inversion every 5 minutes. Tissue was then triturated with a 1.5ml

pipet 15-20 times. A few drops of FBS were then added to stop digestion. Cells

were centrifuged at a rate of 1000 rpm for 10 minutes before the pancreas

solution was removed and replaced with 6 mL of pre-warmed plating medium. Cells

were again dispersed and then counted and adjusted to a maximum of 3.5×105

cells/mL. 2 mL of this cell solution was added to each 35-mm

L-polyornithine-coated dish.

Cells were then observed through a

video microscope (Olympus, 10x ocular, 40x objective) and found to be round and

floating in solution, with diameters of 2 to5μm. Cells were cultured in an

incubator at 37°C in 5% CO2 for 1 hour and then observed. Cells that

were round and plated to the bottom of the sample dish were accepted for use

and samples that did not appear healthy were not used.

2.2 PC12 cells

Feeding media comprised of DMEM

supplemented with high glucose[e], 10% horse serum and 5% fetal

calf serum [f], penicillin (100 U/mL) and

streptomycin (100 μg/mL)[e].

Dish

media for PC12 cells were same[h] as for rat cortical cells.

2.3 Further processes for both types of cells:

After 6 hours of incubation cell

diameters were 5 to 10μm, and cells were observed to be growing neurites. After

12 hours of incubation, neurites had extended about 3 cell body lengths (15 to

30μm) away from the cell. Over a hundred samples were prepared, with about 10%

of our sample dishes left unused because the cells did not appear healthy

(healthy as indicated by cells plating to the bottom of the dish after

incubation).

The experiment was conducted in

sample dishes that were removed from incubation (37 degrees C, 5% CO2) and

placed under a microscope in open air at about 27 degrees C. Sample dishes were

plastic, coated with L-polyornithine which allows the cells to plate onto the

surface, and becomes a uniform traction surface for neurites to physically

interact with. Cells were examined to find growing neurites, cells were

examined at intervals of 30 seconds to find neurites which had moving growth

areas.

Additional

references

1.

Anders, J. J., Borke, R. C., Woolery, S. K. and van de Merwe, W. P. (1993), Low

power laser irradiation alters the rate of regeneration of the rat facial

nerve. Lasers in Surgery and Medicine, 13: 72–82. doi: 10.1002/lsm.1900130113

2.

Higuchi, A., Kitamura, H., Shishimine, K., Konishi, S., Yoon, B.O., and Hara,

M. Visible light is able to regulate neurite outgrowth. J Biomater Sci Polym

Ed14, 1377, 2003.

3.

Higuchi, A., Watanabe, T., Matsubara, Y., Matsuoka, Y., and Hayashi, S.

Regulation of neurite outgrowth by intermittent irradiation of visible light. J

Phys Chem B 109, 11033, 2005.

4.

Higuchi, A., Watanabe, T., Noguchi, Y., Chang, Y., Chen, W.Y., and Matsuoka, Y.

Visible light regulates neurite out-growth of nerve cells. Cytotechnology 54,

181, 2007.

5.

Ehrlicher, A., Betz, T., Stuhrmann, B., Koch, D., Milner, V., Raizen, M.G., and

Kas, J. Guiding neuronal growth with light. Proc Natl Acad Sci USA 99, 16024,

2002.

6.

Wollman, Y., Rochkind, S., and Simantov , R. Low power laser irradiation

enhances migration and neurite sprouting of cultured rat embryonal brain cells.

Neurol Res 18, 467,1996.

7. Daniel

Koch, Timo Betz, Allen Ehrlicher, Michael Gogler, Bjorn Stuhrmann, Josef Kas,

Optical

control of neuronal growth. Proceedings of SPIE. Vol. SPIE-5514, pp. 428-436.

2004

8.

Fiber attenuation data 2.75dB/Km attenuation (at 800nm) - (data from corning.com)

9.

Philip E. Ciddor, Refractive index of air: new equations for the visible and

near infrared. Applied Optics, Vol. 35, Issue 9, pp. 1566-1573 (1996)

10.

P. Scheibener and J. Straub, J.M.H. Levelt Sengers and J.S. Gallagher,

Refractive Index of Water and Steam as Function of Wavelength, Temperature and

Density.

J.

Phys. Chem. Ref. Data 19, 677-715 (1990)

11.

Rei Kitamura, Laurent Pilon, and Miroslaw Jonasz, Optical constants of silica

glass from extreme ultraviolet to far infrared at near room temperature.

Applied

Optics, Vol. 46, Issue 33, pp. 8118-8133 (2007)

12. Harald Ries, Akiba Segal, and Jacob Karni,

Extracting concentrated guided light. Appl. Opt. 36, 2869-2874 (1997)

13. Catherine

E. Graves, Ryan G. McAllister, William J. Rosoff, Jeffrey S. Urbach, Optical

neuronal guidance in three-dimensional matrices.

Journal

of Neuroscience Methods, Volume 179, Issue 2, 15 May 2009, Pages 278–283

14. Allen

Ehrlicher, Timo Betz, Björn Stuhrmann, Michael Gögler, Daniel Koch, Kristian

Franze, Yunbi Lu, Josef Käs, Optical Neuronal Guidance. Methods in Cell

Biology, Volume 83, 2007, Pages 495–520

15. Valeri

Vasioukhin, Christoph Bauer, Mei Yin, Elaine Fuchs, Directed actin

polymerization is the driving force for epithelial cell-cell adhesion. Cell,

Volume 100, Issue 2, 21 January 2000, Pages 209–219

16. Toomas Ku¨

barsepp, Atte Haapalinna, Petri Ka¨ rha¨, Erkki Ikonen, Nonlinearity

measurements of silicon photodetectors. Applied

Optics, 1 May 1998.

Materials

[a] China Medical Science Institute

for Experimental Animal Research - 中国医学科学院医学实验动物研究所

[b] PC12

cells from 2 sources at Peking Union Medical Institute

Cell-Bank - 北京协和细胞库;

and Wang Fei at Peking Union Medical Institute - 北京协和医学院王斐

[c] Sigma-Aldrich Company

[d] Analytical pure, sourced in

China

[e] Thermo Fisher Scientific/Hyclone

[f] Hangzhou Sijiqing Biological

Engineering Materials Co. 杭州四季青公司

[g] Invitrogen/Gibco

[h] Thermo Fisher Scientific/Nunc

[i] Beijing Zhongguancun Zhongfa

Electronics Supply Market, 3160

[j] Narishige MP-830 ocular 15x,

objective 35x

[k] Olympus 10x, 40x

[l] Beijing Viasho Technology Co., Ltd.

Notes

Calculations for the energy of the radiation at

various distances r (in μm) from

the fiber taper tip. The preceeding vn corresponds to locations in figure 6.

v1 r = 1; area

≈ 12μm2/4 = 3μm2; 135mw

/ 3 μm2 =

45mW /μm2

v3 r = 3; area

≈ 113μm2/4 = 28.25μm2; 135mw / 28.25μm2 =

4.8mW /μm2

v5 r = 5; area

≈ 314μm2/4 =78.5μm2; 135mw / 78.5μm2 =

1.72mW /μm2

v7 r = 7; area

≈ 615μm2/4 =153.8μm2; 135mw / 153.8μm2 =

0.88mW /μm2